CT8203

CT8203 – Semight Instruments LT Die Tester

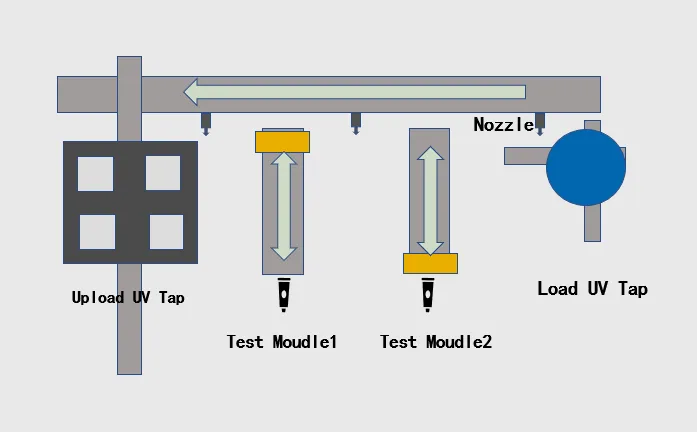

Semight LT Die Tester CT8203 is for the LIV scanning test and spectral scanning test parameter test of the optoelectronic characteristics of the semiconductor LD laser at low temperature and normal temperature. The system is designed with a dual temperature zone structure, and one product can test two temperatures continuously. The system is mainly composed of six parts: wafer supply area, chip handling area, chip position correction area, chip OCR extraction area, chip testing area, and chip storage area. The system integrates wafer ring loading, transportation, DUT ID scanning, high/low temperature testing, unloading and sorting.

CT8203 Support laser forward/backward photoelectric test and forward light spectrum test. It supports two temperature zone tests: two test platforms to support low temperature/normal temperature parallel test.

CT8203 The test efficiency is very high, and the above 6 processes can be completed within 6.5s (1 LIV + 3 spectra). Ideal for high volume production applications. The system adopts eccentric cam structure, high-precision linear motor, high-repeatability stepper motor gauge, high-precision fixture, high-stability power-on probe and high-thermal-conductivity stage, making it ultra-high precision and stability.

- Fully automated and intelligent integrated solutions – Highly integrated and fully automated solution covering very complex testing processes

- High efficiency – Improve efficiency and reduce potential risks of human involvement, Automatic switching of collimated fibers and large area photodetectors, Automatic sorting of DUTs after testing

- Maintenance and upgrades are very simple – All mechanical parts can be returned to the factory independently

- Easy to use – Automatic alarm status and prompt display, All instruments, test plans, pass/fail criteria are easily configurable

Features and Benefits

Fully automated and intelligent integrated solutions

Loading module

This module consists of thimble Z module, X/Y motion module, and blue film rotation module 4 sub-function modules. Pickup function.

Compatibility mode of Chip packaging: 1 x 6-inch chip expansion ring.

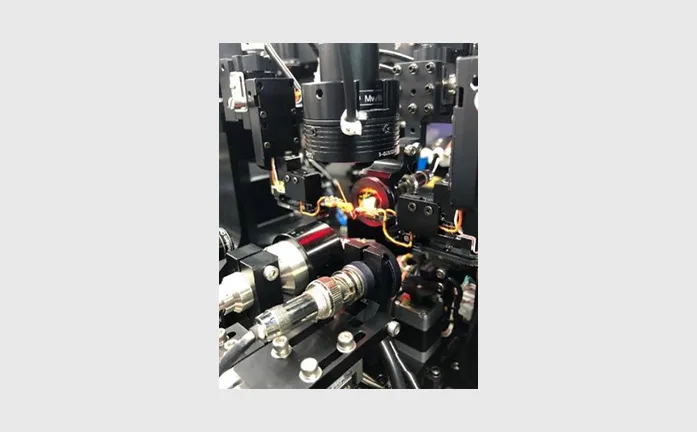

High/low temperature test module

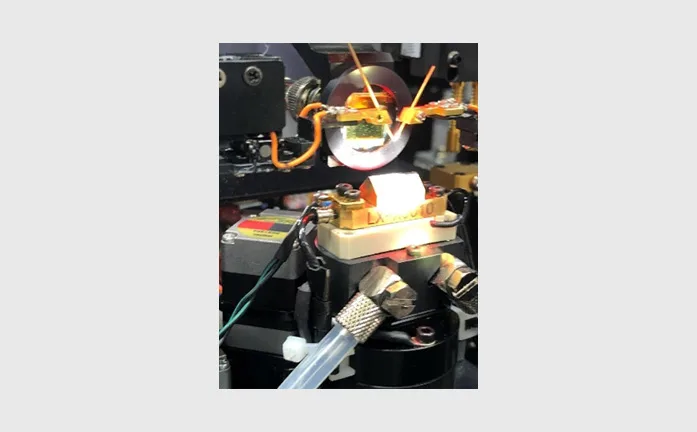

This module is composed of a linear motion module to realize the calibration of three degrees of freedom of Chip, XYθ, a 3-axis light-receiving detection module, an ID/position recognition camera above the module, and a probe power-on adjustment module to complete the feeding. The calibration work of the rear position angle, and the chip test power-up work. The PD/collimator uses a motion axis for fast switching of functions.

The temperature of the test bench can be independently set according to the process, and the temperature stability is <±0.2°.

Camera, probe power-on module

The feeding camera on the right side of the equipment is matched with the feeding module to complete the feeding recognition function of the Chip (different functional components can be matched according to the incoming material requirements), and complete the position calibration of the Chip by taking multiple photos with a 3-axis motion module (the camera can synchronize the ID identification of the Chip).

Probe power-on module, each set is equipped with up to 3 sets of probes (backlight PD sub-function module is optional), different combinations can realize LIV, EA, spectrum and other related parameters of DFB / EML, EML+SOA products ‘s test.

Blanking binning module

The blanking module is equipped with 4 carrier tray placement areas, which can support 4 6-inch blue films, or customize compatible blanking carriers according to customer needs.

| Parameter Type | Parameter name | Parameter index |

| System functions | DUT Type | Compatible with customer-specified DFB, EML and EML+SOA Die tests (according to the difference in cavity length and size between DFB and EML, the test stage can be selected to be compatible or incompatible) |

| Test items | Laser front light and backlight LIV, EML extinction ratio and spectral test | |

| Test seat | 2 | |

| ID identification | Support Chip ID identification | |

| Chip size | L&W≥150 μm, H≥80~150 μm | |

| Nozzle structure | Specially designed suction nozzle structure, first peeled from the material box, and then sucked up | |

| Test Parameters | Ith, Se, Iop, Pf, Vf,I r, PKink, Ikink, Rd, Pmax, IRoll, ER, λc, SMSR and other nearly 100 parameters,Support any requirements customer need | |

| Loading Container | Supports 1 6-inch blue film | |

| Unloading Container | Supports four 6-inch blue films | |

| Blanking and grading | The materials are classified according to the identification and test results, and the material classification conditions can be edited in the software according to customer requirements | |

| CDA requirements | >600L/Min(If less than this flow will affect the dew point speed) | |

| Electrical parameters | Source meter unit type | Semight self-developed SMU or other specified types |

| Number of SMU | 3 dual-channel source meters for DFB lasers, 4 dual-channel source meters for EML lasers, and 5 dual-channel source meters for EML+SOA lasers | |

| Power up type | Support CW and Pulse power up | |

| DC current | 3A, 1A, 100mA, 10mA, 1mA, 100μA | |

| Minimum Power Resolution | 20μA, 5μA, 500nA, 50nA, 5nA, 500pA | |

| Minimum measurement accuracy | 0.03%+50 nA | |

| DC voltage source range | 30V, 10V, 1V | |

| Voltage resolution | 100μV, 10μV, 1μV | |

| Minimum voltage measurement accuracy | 0.02%+1 mV | |

| Minimum pulse width | 250 μs | |

| Normal operation undershoot | NO EOS | |

| Normal operation undershoot | NO EOS | |

| Normal operation undershoot | NO EOS | |

| Abnormal operation overshoot | NO EOS | |

| Light parameters | Detector type | Ge |

| Optical power detection wavelength range | 800-1700 nm | |

| Optical power measurement range | 10 μW-25 mW(>25 mW Attenuator measurement can be added) | |

| Spectral test wavelength range | Customer supplied spectrometer or Yokogawa AQ6360 | |

| Spectral Test Accuracy | Customer supplied spectrometer or Yokogawa AQ6360 | |

| EA DCER precision | ±0.2 dB | |

| Temperature | Temperature control method | TEC+water cooling (with dew point monitoring, the dew point can be within -70 ℃) |

| Temperature range | -40~95 ℃ | |

| Temperature rise rate | Room temperature rises to 90 ℃ < 5 minutes | |

| Temperature drop rate | Room temperature dropped to -40 ℃ <10 minutes | |

| Temperature accuracy | ±0.5 ℃ | |

| Temperature stability | ±0.2 ℃ | |

| System metrics | Ith repeatability | ±1% |

| Power Repeatability | ±2% | |

| Wavelength repeatability | <±0.2 nm | |

| SMSR Repeatability | <3 dB | |

| ID identification one-time success rate | >99.5% | |

| Test time | Complete all operations within 6.5 s (EML chips will vary according to different test items) |