Standard, DIY & Custom Cold Plates

Standard, DIY & Custom High-Performance Cool Plates

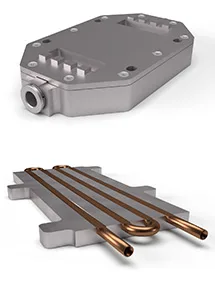

When cooling IGBT modules and high-powered semiconductors,air cooling is often inadequate and liquid cooling is required. Cold plates are a way to implement localized cooling of power electronics by transferring heat from the device to a liquid that flows to a remote heat exchanger and dissipates into either the ambient or to another liquid in a secondary cooling system.

The internal,mini-channel fin structure enhances the surface area to maximize heat transfer with low pressure drop characteristics and provides uniform cold plate surface temperature.

To give engineers more freedom to apply Cold Plates to specific applications,ATS has taken the Standard Cold Plate family and created a DIY (“Do It Yourself”) family . The DIY Cold Plate family has the same thermal performance as the Standard Cold Plate family except that holes may be drilled in them to create a mounting pattern to match the specific connection points of the device being cooled. Each cold plate includes an etched “no drill zone” to provide a visual guide. After an engineer is satisfied with the mounting,ATS can manufacture their custom cold plates for prototypes or production.

Standard, DIY & Custom High-Performance Cool Plates

- More than 30% improvement in thermal performance compared to commercially-available cold plates

- Compatible with industry accepted coolants

- 1/4 (pipe size) –18 (thread density) NPT threaded input and output

- Low pressure drop

- Lightweight for ease of use

- Provides uniform cold plate surface temperature when IGBTs are installed

- Leak tested at 100 psi

- Customizable to fit different devices

- What is a cold plate and how does it Work?

- Selecting and Designing Liquid Cold Plates for Deployment in Electronic Systems – ATS Webinar Series

- ATS Copper Tubed Cold Plates Overview

- ATS Stainless Steel Tubed Cold Plate Overview

- iFLOW-200 Cold Plate Characterization System

- ATS DIY Cold Plates

- ATS High Performance Cold Plates

- Automotive

- Instruments

- Uninterruptible Power Supplies

- Wind Turbines

- Photovoltaic Inverters

- Induction Heaters

- Motor Devices

- High Powered Industrial Lasers

- Battery Cooling

- Many high-power,high-heat flux applications

* If you need Datasheet, CAD or RoHS, please contact us.

| Part Number | Lifecycle Status |

Dimension (mm) | Material | Thermal Resistance Based on 1kW Heat Dissipation & 4 L/min Flow Rate (°C/W) |

||

|---|---|---|---|---|---|---|

| L | W | T | ||||

| ATS-CP-1000 | ACTIVE | 202 | 130 | 20 | Aluminum | 5.5 |

| ATS-CP-1001 | ACTIVE | 198 | 147 | 20 | Aluminum | 5 |

| ATS-CP-1002 | ACTIVE | 162 | 136 | 20 | Aluminum | 7 |

| ATS-CP-1003 | ACTIVE | 162 | 147 | 20 | Aluminum | 6.8 |

| ATS-CP-1004 | ACTIVE | 162 | 172 | 20 | Aluminum | 5.9 |

| ATS-CP-1000-DIY | ACTIVE | 202 | 130 | 20 | Aluminum | 5.5 |

| ATS-CP-1001-DIY | ACTIVE | 198 | 147 | 20 | Aluminum | 5 |

| ATS-CP-1002-DIY | ACTIVE | 162 | 136 | 20 | Aluminum | 7 |

| ATS-CP-1003-DIY | ACTIVE | 162 | 147 | 20 | Aluminum | 6.8 |

| ATS-CP-1004-DIY | ACTIVE | 162 | 172 | 20 | Aluminum | 5.9 |

| ATS-CP-2001 | ACTIVE | 235 | 85 | 22 | Aluminum | 7.3 |

| ATS-CP-2002 | ACTIVE | 206 | 172 | 22 | STAINLESS STEEL 3O4 | 4.6 |

| ATS-CP-2005 | ACTIVE | 198 | 147 | 20 | Aluminum | 65.8 |

| ATS-CP-2010 | ACTIVE | 540 | 172 | 29 | Aluminum | 3.5 |

| ATS-CP-2014 | ACTIVE | 248 | 76.7 | 29 | Aluminum | 12 |

| ATS-CP-2015 | ACTIVE | 115 | 87 | 20 | Aluminum | 24.7 |

| ATS-CP-2027 | ACTIVE | 198 | 147 | 26 | Aluminum | 5.5 |

| ATS-CP-2028 | ACTIVE | 162 | 136 | 26 | Aluminum | 7.7 |

| ATS-CP-2029 | ACTIVE | 162 | 172 | 26 | Aluminum | 6.5 |