New requirements for vehicle specification level power semiconductor testing

Vehicle-Grade Power Semiconductor Test – Semight Instruments Reliability Solution

According to the bathtub curve theory, any electronic component will have a high failure rate at the beginning of its life cycle, and the failure rate will obviously drop to the stable period with the passage of time.

Vehicle-Grade Power Semiconductor Test – Semight Instruments Reliability Solution

Different from consumer grade products, automobiles will operate in harsh environments such as outdoor, high temperature, cold and humid, and the design life is generally 15 years or 200000 kilometers. The iteration cycle will be much higher than that of consumer electronics for 2-3 years, and the requirements on environment, vibration, impact, reliability and consistency are also high. Therefore, automobile enterprises usually require suppliers to use vehicle grade components to ensure the quality and reliability of on-board ECU products.

- Higher voltage current

- SiC needs higher test current and voltage test

- 1700V MOSFET has been mature, and subsequent 3300v demand

- Higher switching speed

- SiC / GaN requires higher switching speed test

- Higher reliability

- Before packaging, it must be ensured that the chip with complete reliability is used for packaging

- Higher packaging density

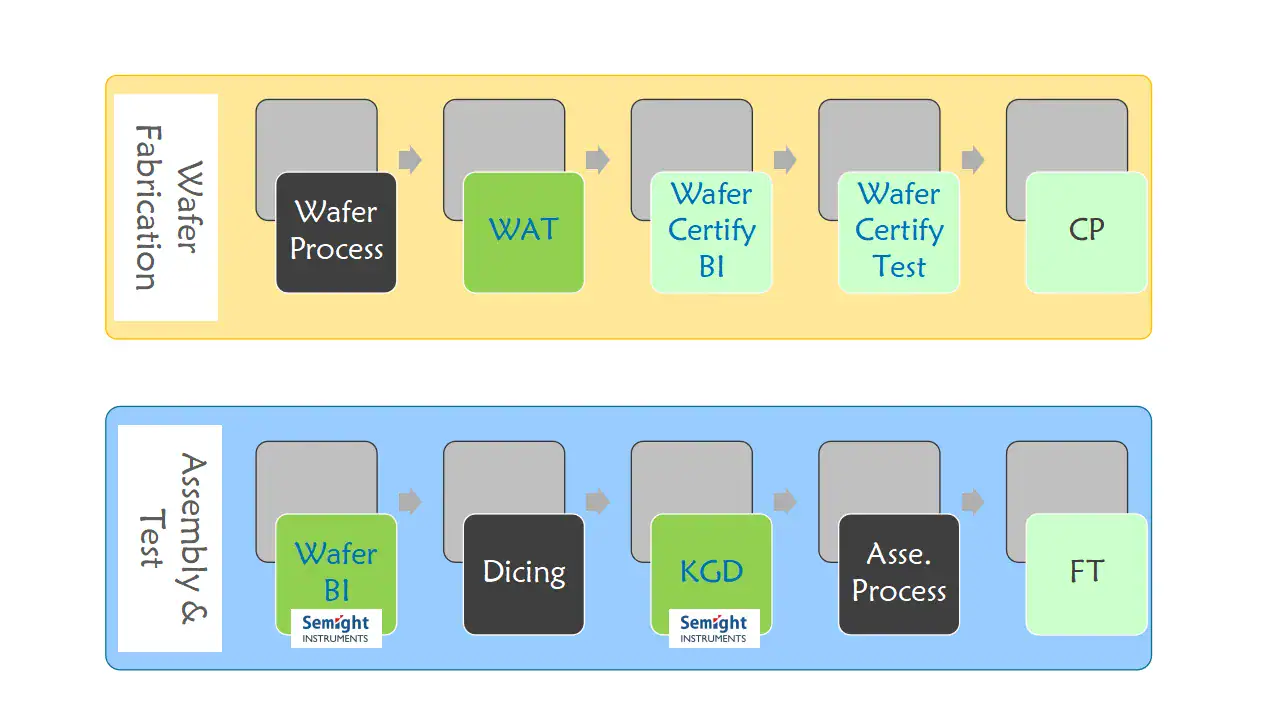

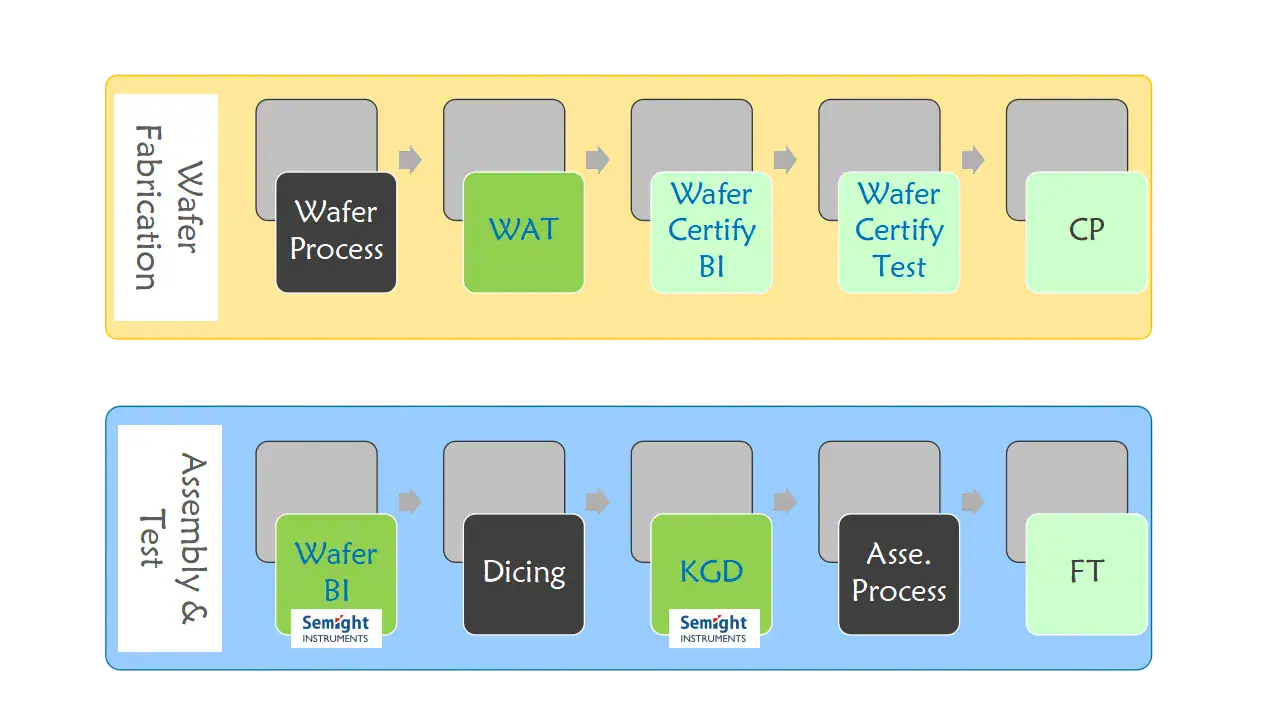

With the mission of continuously filling the gap of domestic high-end optoelectronic testing equipment, Semight has developed semiconductor chip testing machine (silicon carbide KGD testing machine PB6200&PT6200), wafer level reliability (silicon carbide high-voltage wafer aging WLR3500) and other equipment in combination with its core advantages, such as weak signal detection, high-power signal detection and complex probe system design, Help the high-speed and high-quality development of domestic power devices.

With the mission of continuously filling the gap of domestic high-end optoelectronic testing equipment, Semight has developed semiconductor chip testing machine (silicon carbide KGD testing machine PB6200&PT6200), wafer level reliability (silicon carbide high-voltage wafer aging WLR3500) and other equipment in combination with its core advantages, such as weak signal detection, high-power signal detection and complex probe system design, Help the high-speed and high-quality development of domestic power devices.