WLBI3800

Wafer level Burn-in System

WLBI3800 is a professional silicon carbide wafer burn-in test equipment. It can simultaneously perform HTGB burn-in and HTRB burn-in on three wafers. The burn-in test time range is extensive, spinning from a few minutes to thousands of hours, meeting the burn-in requirements of various products. The equipment integrates an automatic loading and unloading system with dual cassette design. It features automatic switching of burn-in conditions and can precisely detect the threshold voltage (Vth) of each die. Each channel of the system has independent overcurrent protection to ensure the safety of the tested devices.

WLBI3800 – Semight Instruments Wafer Level Burn-In System

- Automated Loading and Unloading – Fully automated wafer handling minimizes manual intervention, boosting efficiency and accuracy

- Precise Probing – Delivers ±25μm probe mark repositioning accuracy for reliable testing

- Comprehensive System Features – Supports map data binding for traceability and testing up to 2112 dies simultaneously

- Multimode Burn-in – Automatically switches between HTGB and HTRB modes

- Leakage Current Monitoring – Igss and Idss leakage current monitoring

- Integrated Testing Functions –Includes Vth parameter testing for in-depth analysis

- Exceptional Measurement Accuracy – Offers maximum resolution of 0.1nA

- Precise Temperature Control –Ensures uniformity within ±3℃, accuracy within 1℃, and resolution of 0.1℃

Functions and advantages

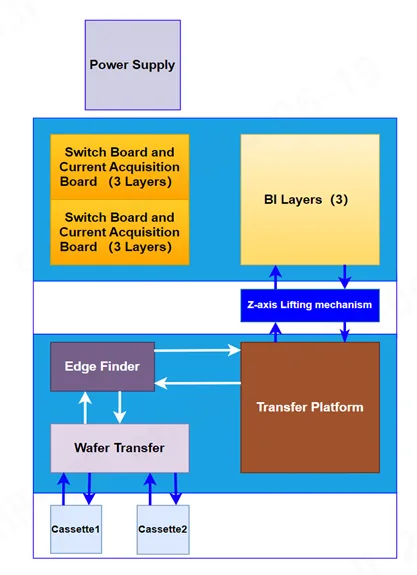

System Configuration

The system supports up to three independent layers, each equipped with its own fixture and independently controlled circuits. This design allows each layer to operate in different modes, enabling flexible burn-in verification through customizable burn-in plans.

The specific configuration is as follows:

| No. | Module | Part Number | Description |

| 1 | System Cabinet | WLBI3800-M | Includes system rack, electrical cabinet, and loading/unloading machine

Supports fully automated wafer loading and unloading Achieves Probe mark repositioning accuracy of ±25μm Supports map data binding with traceable data Automatically switches between HTGB and HTRB modes Test Igss and Idss leakage Integrates Vth parameter testing Offers flexible configuration of burn-in plans Supports SECS/GEM communication interface Software supports local data and database uploads, and EAP integration Supports CP map data import Supports online editing of test recipes Software supports three-level permission management and multi-account management Note: HTGB + HTRB: Fully configured with 3 layers |

| 2 | Burn-in Layer | WLBI3800-L | High-precision leakage current testing with a maximum resolution of 0.1nA.

Supports nitrogen protection to prevent high-voltage arcing and pad oxidation. Temperature uniformity ≤±3℃, accuracy ≤1℃, resolution 0.1℃. High-density probe cards and support for high-voltage chuck. High-precision and high-reliability heating and temperature control system. Compatible with 6- and 8-inch wafers. Full touch interface allowing simultaneous burn-in up to 2112 dies. One year of free maintenance. Note: HTGB + HTRB: Fully configured with 3 layers.

|

| 3 | Burn-in Fixture | WLBI3800-F | Designed for SiC wafer burn in: HTGB + HTRB

Supports 6- and 8-inch wafers Supports up to 2112 dies |